Mission and objectives

The Liquid Hydrogen Initiative is a business-plan and proposal of development of Cloud based industrial software complex for Engineering Calculations, Risk-based inspection, Mechanical integrity, NDT (Nondestructive testing), and Fluid management aimed to advance the technology of Renewable and sustainable fuels that is crucial to the United States' leadership in the global market.

The proposed software program will be designed to manage and make decisions in the field of technical reliability of enterprises, based on the planning of maintenance and repair work of equipment working under pressure (Fig 1, Fig 2), based on a risk assessment based on the actual condition.

Fig 1. Locking devices working under pressure

Users of the program are system analysts, metrologists, and decision-makers in the maintenance and operation of equipment operating under pressure, such as gas-filled installations, tanks, and pipelines used for the transportation and storage of aerospace and refinery liquids.

Fig 2. New Cryogenic Tank arrived at NASA

High demand for software in the field of Engineering Calculations and Fluid Management

- OCTOBER 13, 2023

Biden-Harris Administration Announces $7 Billion For America’s First Clean Hydrogen Hubs, Driving Clean Manufacturing and Delivering New Economic Opportunities Nationwide

- MARCH 15, 2023

Biden-Harris Administration Announces $750 Million to Advance Clean Hydrogen Technologies

The need to develop software for managing the condition of equipment for the transportation and production of liquid energy carriers is determined by the high demand of the state for technologies related to the production and transportation of liquid hydrogen. Therefore, this software will be highly in demand in the US market in the coming years.

«Making clean hydrogen from abundant renewable energy provides America with yet another incredibly powerful fuel for many different applications, from low-emissions use in the construction and manufacturing industries to energy storage to powering our cars and trucks, » said U.S. Secretary of Energy Jennifer M. Granholm. «Thanks to new funding from President Biden’s historic clean energy laws, DOE is accelerating our effort to make this exciting and versatile fuel market-ready within a decade—supercharging America’s drive towards an affordable and secure clean energy economy.»

Target market

The target market for the proposed software is a wide spectrum of enterprises in the refinery and aerospace sector, engaged in the production and transportation of liquid energy carriers particularly liquid hydrogen. Covering the scope of needs of technologies known as Hydrogen fuel cell.

- Hydrogen fuel cell

Hydrogen fuel cells produce electricity by combining hydrogen and oxygen atoms. Hydrogen reacts with oxygen across an electrochemical cell— similar to a battery—to produce electricity, water, and small amounts of heat.

For example: an 80-liter vessel can accumulate energy of ~1000 MJ. An electric car with a fuel cell at such a gas station will travel ~800 km. And with energy recovery for 1200 km.

Nearly all of the hydrogen consumed in the United States is used by industry for refining petroleum, treating metals, producing fertilizer and other chemicals, and processing foods. U.S. petroleum refineries use hydrogen to lower the sulfur content of fuels. Biofuel producers also use hydrogen to produce hydrotreated vegetable oil (HVO) for use as renewable diesel.

Market analysis

I’ve extensively researched the Global Hydrogen Market using such agencies as:

GMI Global Market Insights https://www.gminsights.com.

AMR Allied Market Research https://www.alliedmarketresearch.com

The U.S. Department of Energy https://www.hydrogen.energy.gov

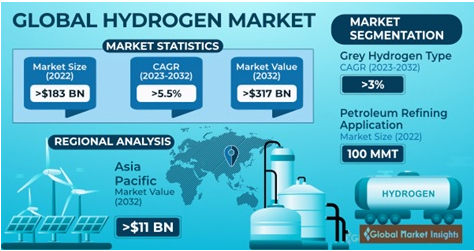

According to GMI (see Fig 3) the Hydrogen market size surpassed USD 183 billion in 2022 and is expected to expand by USD 317 billion

Fig 3. Global Market Insights Report on Hydrogen Market

The market for liquid hydrogen is rapidly growing, with a compound annual growth rate (CARG) of 5.5%, indicating a strong demand for hydrogen transportation and storage equipment.

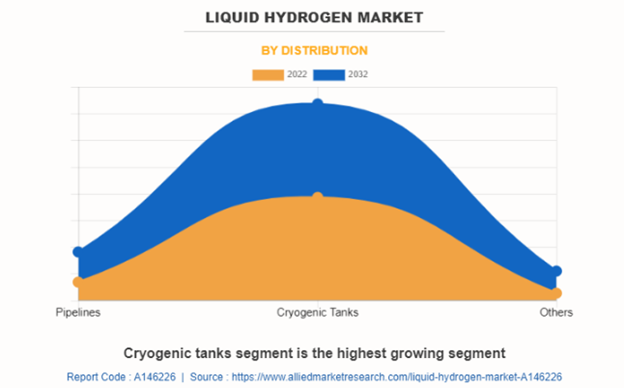

According to AMR, by distribution, the cryogenic tanks segment dominated the global market in 2022 and is anticipated to grow at a CAGR of 5.6% during the forecast period. Cryogenic tanks are essential for storing & transporting liquefied gases such as liquid hydrogen, liquid oxygen, and liquefied natural gas (LNG). As various industries expand, the demand for cryogenic tanks increases to support the storage & transport sectors. In addition, tanks are utilized in the storage and transportation of liquid hydrogen, which has gained popularity as a cleaner alternative to traditional fossil fuels. With the increasing demand for natural gas as an energy source, especially in power generation and transportation, there is a corresponding rise in the demand for cryogenic tanks to support the infrastructure required for liquid hydrogen storage and distribution. This factor is projected to boost market growth during the forecast period.

Fig 4. Allied Market Research on Cryogenic Tanks

On the graph, we see that the production of Cryogenic Tanks and Pipelines will at least double by 2032.

To maintain the state of cryogenic and other pipeline equipment, the software layer is required for a system for its current state (thickness), risk management associated with leaks, accidents, transportation, and engineering calculations necessary for controlling fluid consumption.

The growth of the Hydrogen Fuel Cell industry is not possible without the presence of dedicated software designed for thickness measurement control, operation risk management, fluid management, and integration with non-destructive testing (NDT) services, so the provision of such software is essentially a task of national importance.

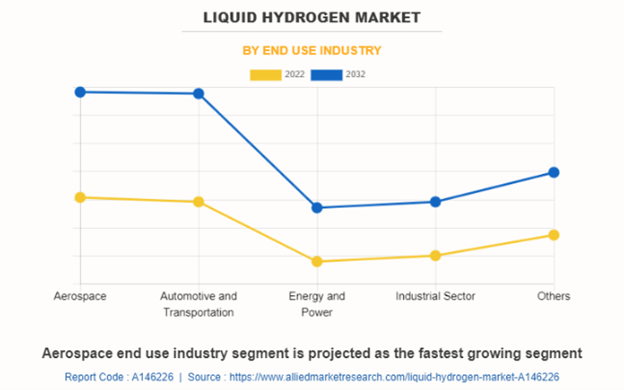

My project will be focused on the Aerospace industry

Fig 5. Allied Market Research on Industry Sectors

In 2022, the aerospace segment was the largest revenue generator and is anticipated to grow at a CAGR of 5.7% during the forecast period. Liquid hydrogen offers a high specific impulse, which is a measure of the efficiency of a rocket engine. It provides a greater thrust per unit of propellant compared to other fuels, allowing for higher velocities and payloads. The high specific impulse of liquid hydrogen makes it a preferred choice for achieving the demanding performance requirements of space missions. In addition, the aerospace industry is focusing on reducing aerospace's environmental impact and transitioning toward more sustainable practices. Liquid hydrogen is a clean fuel and it burns oxygen and tends to produce water vapor. Its use as a propellant significantly reduces greenhouse gas emissions compared to traditional fossil fuel-based propulsion systems.

The need to create application software for the LH2

Liquid Hydrogen Storage & Conveying Equipment is equipment that is corroded by metal and operates under pressure. Accordingly, for the regular operation of this equipment, a prerequisite is the maintenance of this infrastructure in a safe, working condition. Hence the requirement to develop this specific software for thickness measurement control, operational risk management, fluid management, and integration with non-destructive testing (NDT) services.

Job creation

As the growth of infrastructure in the Hydrogen Fuel Cell sector will itself lead to the creation of additional jobs for NDT and metrology professionals who operate the equipment directly, higher-level analysts will be required to ensure overall physical security and decision-making in this area, whose work will be directly related to data analysis and work with the program. which I propose. Thus, the program I propose will create jobs for analysts who make decisions in this sector.

Sustainable economic development

The number of such jobs will proportionally double by 2032 about the existing one, in companies in this sector today it will double. However, it is worth noting that, first of all, the increase in the reliability of equipment operation in this industry, offered by my program, is a guarantee of the growth of the industry itself. In other words, the growth of the Hydrogen Fuel Cell sector is not possible without the right software.

Prospective customers of my software

The global liquid hydrogen market profiles leading players that include Iwatani Corporation, Messer Group GmbH., inoxcva, Air Products and Chemicals, Inc., Demaco powered by Leapforce, Linde Plc, Air Liquide, Cryostar, Hylium Industries, Inc., and Plug Power Inc. The market report provides in-depth competitive analysis as well as profiles of these major players.

Specific details about future software

The final objective of the software is to calculate the Total Financial Cost of a particular fluid management project to make business decisions.

For static onshore equipment, the primary risk-based planning methodology widely used in refineries and petrochemical plants around the world is the RBI (Risk Based Inspections) methodology developed by the American Petroleum Institute (API) and outlined in the API-571, API-580, and API-581 standards. This practice applies to pressure vessels, piping, and tanks, as well as to safety valves.

According to this methodology, the probability of equipment failure and the consequences of this failure will be assessed, the magnitude of the risk will be determined as their product, and based on the magnitude of the risk, a forecast for the future will be made. The assessment of the probability of an accident is based on statistical indicators, considering the specific features and conditions of the equipment, as well as the effectiveness of surveys. Technical inspections are considered measures that confirm the reliability of equipment with a certain accuracy.

A huge amount of data is required to correctly create equipment inspection plans and evaluate survey results. The software will allow US businesses in the Aerospace field to collect, analyze, organize, and document the information that is necessary to maintain the performance of equipment and prevent accidents and leaks.

The software will consolidate and organize all equipment and survey results (equipment design data, operating parameters, drawings, documentation, survey history, repairs, reports, and survey plans) and place them all in one accessible and user-friendly cloud system.

The software will automatically create plans for future surveys based on 3 maintenance planning principles:

- based on fixed survey intervals (traditional approach)

- based on corrosion rate calculations and residual life estimates

- Based on Risk Assessment (RBI)

The software will be a cloud-based database (Cloud DB) that records and then analyzes data from equipment inspections, determines corrosion rates, follow-up inspection dates, decommissioning deadlines, and identifies suspicious areas that require additional surveys.

One of the most important components of the future system is the Fluid Expense Calculator, a tool that allows you to estimate the flow rate of physical liquids in drums, liters, or kg3/sec, considering parameters such as fluid type, temperature, pressure, opening size, release time and other physical parameters. Most of the known implementations of such tools are part of desktop software and have drawbacks such as the lack of capability integration, scalability, and platform dependency. This is a software tool that implements calculations based on the provided mathematical formulas, input parameters, variables, and constants. Variables, in turn, can depend on other variables, constants, or formulas. The engine is deeply integrated with the relational database and combining it with AI and Cloud computing will make its operation more flexible and globally available.

The purpose of the future software is to calculate but not only. Also, the software will assist in deciding on the following areas:

- Cost to repair

- Damage to surrounding equipment

- Downtime required to repair the surrounding equipment

- Cost of business interruption

- Environmental cleanup costs

- Total Financial Cost

Novelty of the future product

The future project will be implemented completely Cloud Based, offering customers a SaaS platform (Software as a Service) model.

The future project will be promoting API 581 Risk Based Inspection methodology and ASME standards.

The future project will offer a software layer for mobile clients thanks to the universality of the REST technology stack.

The Cloud service of the Engineering Calculator will be developed and built with the Firemonkey library on RAD Studio 12 Delphi to allow deployment on Linux-64-bit systems such as Ubuntu 22.04, which in turn will allow to lower the cost of ownership for customers.

My background, Achievements to date

Konnov Software Development (as self-employed) has been providing extreme quality software development services for its valuable clients since 2012.

I have 25+ years' experience in development of software for industrial automation, calibration, AIM, MES, LIMS, SCADA, FIDS, CMMS.

- Co-author of state patent Visinform3

- Co-author of Delphi26 award ShowCase Challenge - “Syncovery”

- Author of publication in Blaize Pascal Magazine

- Author of monograph SCADA approach in APCS

To progress this endeavor, I will utilize my extensive experience in the field of AIM (Asset Instrumentation Management), LIMS (Laboratory Information Management System), FIDS (Flight Information Display System), ASAC (Automates System of Analytical Control) SCADA (Supervisory Control and Data Acquisition) and Cloud Technologies from Syncovery project.

My strongest skill in programming is knowledge and experience of implementation of multi-tier or middleware services utilizing TCP/IP Socket, REST/SOAP technology for communication with client software, which in turn requires knowledge of multithreading programming and relational databases knowledge that I possess on the highest level. Software developed by me is running on thousands of computers nationwide 24/7 commercially without my support for many years.

How will I directly implement my project?

Client software will interact with the Cloud Service based on REST technology and use methods provided by the API. I’ve created and maintained a demo OpenSource prototype CryoFM API, which allows me to discuss the immediate requirements of the future program with the customer.

What benefits will my endeavor bring to the US as a nation?

My specific venture Cloud based industrial software complex for Engineering Calculations, Risk Based Inspection, Mechanical integrity, NDT (Nondestructive testing) and Fluid management is poised widely and positively to affect the energetic independence of the USA. The software suite will enable diverse businesses across industries such as refinery, energy, and aerospace, who oversee their industrial machinery, to adopt a unified engineering standard from the American Petroleum Institute (API 581). This includes access to a comprehensive database and algorithm for fluid flow calculations, management of thickness measurements, and non-destructive testing (NDT) data nationwide. As a result, it will enhance the efficiency and consistency of business transactions, foster alignment in risk assessment methodologies, and ultimately bolster the reliability of the nation's aerospace and energy sectors. Additionally, it will create opportunities for new jobs in the realm of analytical control and decision-making and as a positive consequence it will create new jobs in depressive areas related to servicing of liquid hydrogen infrastructure.

Sincerely,

Dmitrii V. Konnov